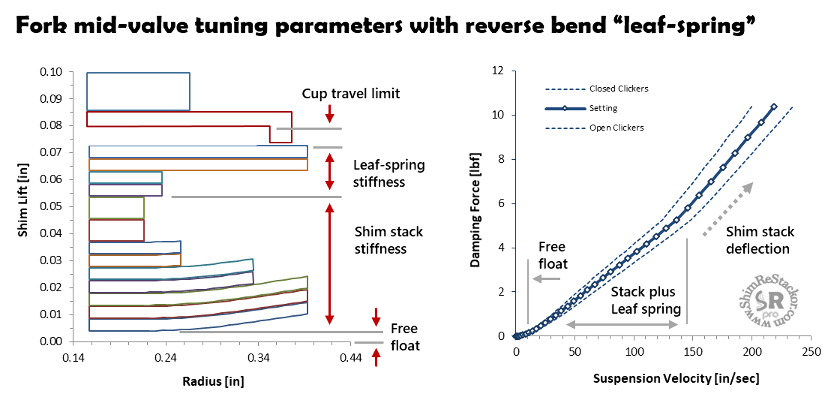

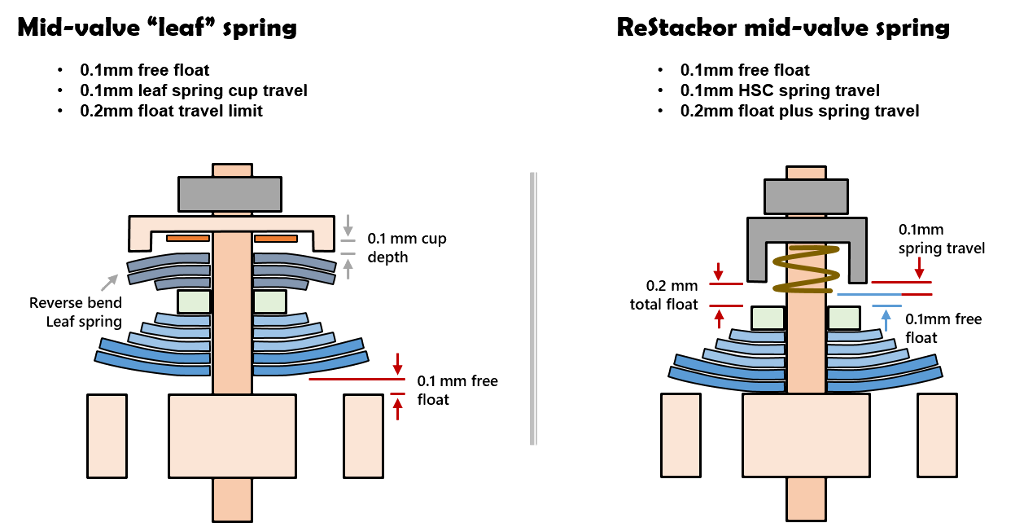

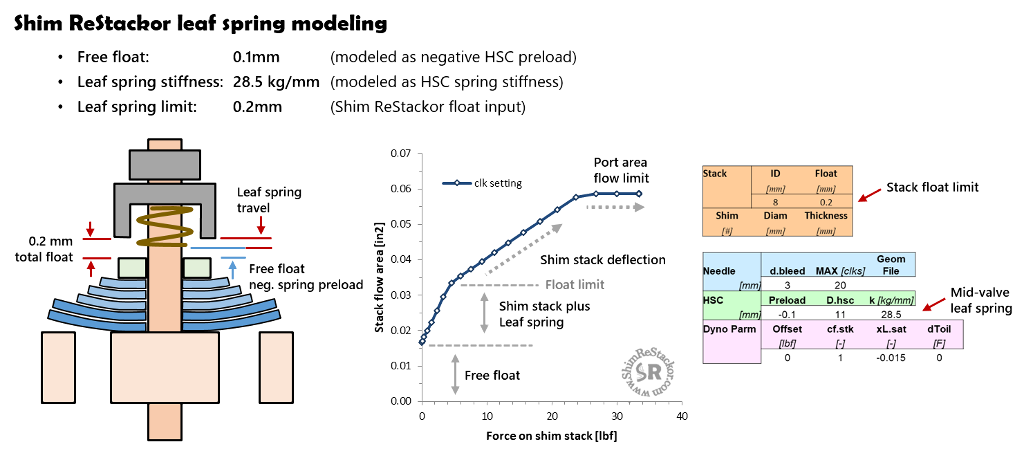

A fork midvalve “leaf-spring” is a stack of shims above the clamp that bend backward into the clamp washer cup, also known as a trampoline valve. Deflection of the leaf-spring floats the shim stack. Spacers in the cup limit the leaf-spring travel and the maximum stack float.

Shim ReStackor models leaf-springs using the high speed compression adjuster (HSC) inputs. Negative spring preload specifies free-float. The HSC coil spring stiffness specifies the stiffness of the leaf-spring and the shim stack float input specifies the max float travel where the leaf-springs bottom in the clamp washer cup.

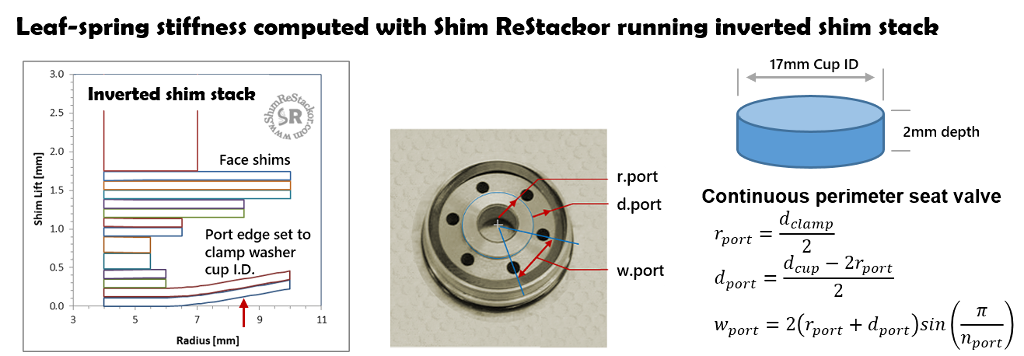

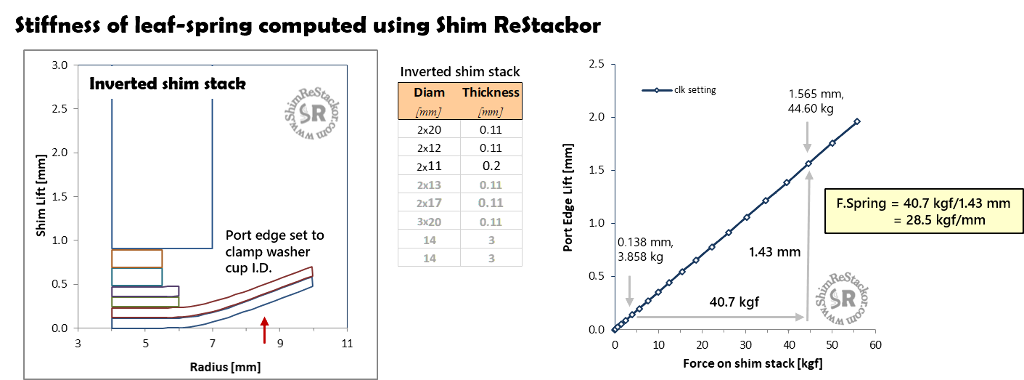

Leaf-spring stiffness

Stiffness of the reverse bend leaf-spring is determined running a separate Shim ReStackor calculation with the shim stack inverted. The inverted stack puts the leaf-springs on the valve face.

The valve is configured as a perimeter seat valve with the seat diameter matching the clamp washer cup. The stack clamp diameter of the leaf-spring defines r.port and the clamp washer cup radius defines r.port + d.port.

The port edge lift computed by Shim ReStackor gives a direct measure of leaf-spring stiffness. Over the 2mm of clamp washer cup travel the leaf-spring stiffness is nearly linear. Linear stiffness makes the HSC coil spring used in Shim ReStackor modeling a good approximation.

The spring rate of the leaf-spring is simply force divided by displacement. Picking points off of the computed port edge lift curve shows the leaf-spring stiffness is 28.5 kgf/mm.

Leaf-spring tuning

Three Shim ReStackor inputs define leaf-spring performance:

Negative spring preload: Negative preload allows the stack to free-float before engaging the HSC coil spring. In the example free float is 0.1 mm.

HSC spring stiffness: Deflection stiffness of the leaf-spring is modeled using the HSC coil spring.

Fluid force applied on the shim stack face compresses the HSC spring progressively increasing the shim stack float.

Float: The Shim ReStackor float input defines the travel limit. At the float travel limit, the stack clamp hits a hard stop equivalent to bottoming the leaf spring in the cup.

Fork mid-valve tuning

Free-float sets the suspension velocity where the mid-valve begins generating compression damping force. Free-float is set by negative HSC spring preload.

In the second range, the combined deflection of the shim stack and reverse bend leaf-spring controls the valve port flow area and damping force. Modifying the leaf spring stiffness controls the slope of the curve through the second range.

At 150 in/sec the leaf-spring bottoms in the clamp washer cup. The Shim ReStackor float input specifies the leaf-spring travel limit.

After the leaf spring bottoms, the deflection stiffness of the shim stack becomes the single parameter controlling flow area and damping force.

At ultra-high speed the valve port throat area limits the flow creating a fourth damping force range.

Shim ReStackor models all four ranges. Parameters controlling the start and end of each range are tunable as well as the damping force through each range. Leaf-springs can be tuned for control of low speed float as in the example or as a high speed blow-off system.