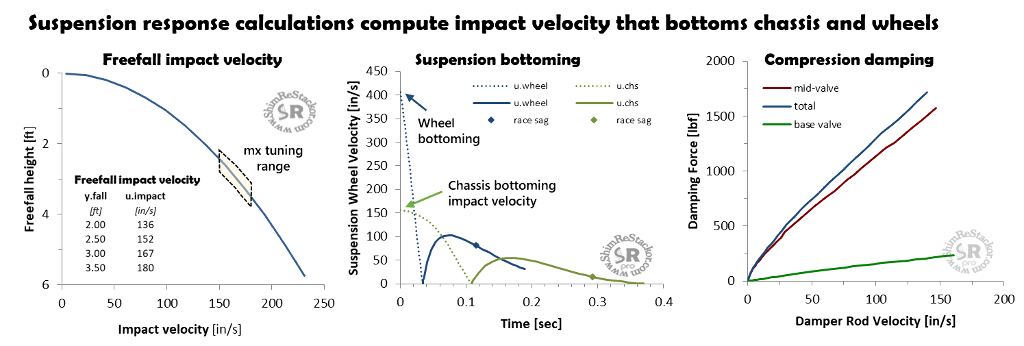

Damping, spring rate and link ratio define the jump landing impact that bottoms suspensions. The Shim ReStackor shock revalving calculator combines those three parameters in suspension response calculations to determine the jump landing impact velocity that drives the suspension to the max stroke depth specified in the inputs.

- Wheel bottoming: Bump impact velocity required to drive the wheels from race sag to the specified stroke depth

- Chassis bottoming: Jump landing impact velocity for the combination of bike plus rider weight to drive the suspension from full extension to the specified stroke depth

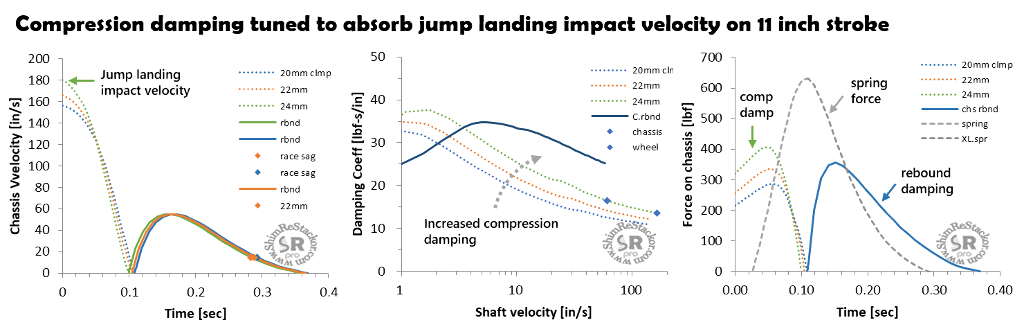

Tuning suspensions to absorb a target jump landing is straight forward and simply requires hacking around on the shock absorber compression shim stacks or spring rate to hit the target jump landing impact velocity.

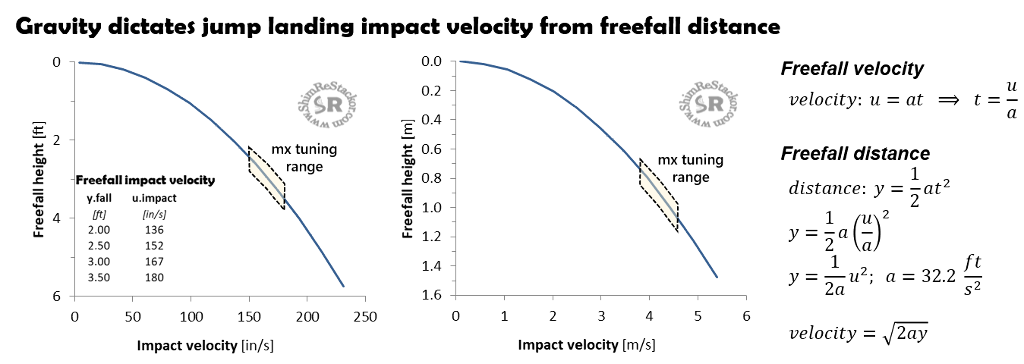

Jump landing impact velocity

Gravity dictates jump landing impact velocities. MX setups are typically tuned to flatland 2.5 to 3.5 foot jump landings producing impact velocities from 152 to 180 in/sec.

The example below tunes compression damping to absorb a 167 in/sec impact velocity equivalent to landing a three foot jump freefall.

Shim stack tuning for suspension bottoming control

Inputs of spring rate, link ratio and race sag specify the chassis plus rider weight. Response calculations compute the impact velocity required to drive the suspension from full extension to the input specified “Max Stroke” depth, in this case 11 inches.

Increasing the shim stack clamp diameter from 20 to 22 mm increases the jump landing bottoming velocity from 156 to 165 in/sec. Adding an additional face shim increases the bottoming velocity to the target 167 in/sec impact velocity for a 3 foot jump landing.

On the fielded setup, the suspension bump rubber adds additional margin to the bottoming velocity on an 11 inch stroke.

Bump compliance

Stiff compression damping required for jump landings causes the chassis to deflect off square edge root and rock impacts. Shim ReStackor suspension response calculations quantify the problem.

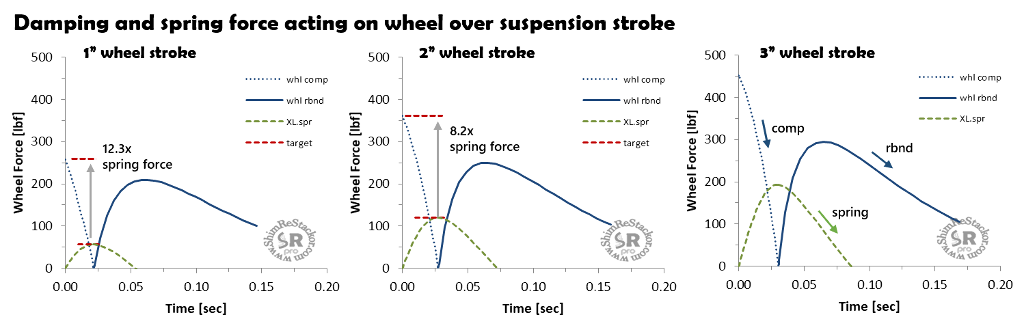

Running the shim stack configuration tuned above for jump landing on a one inch wheel bump stroke shows the compression damping force at bump impact is 12.3 times stiffer than the peak spring force.

Compression damping stiffer than the peak spring force produces a “bang” at bump impact making the suspension “feel” harsh. Installing a crossover in the compression shim stack softens low speed damping and tuning the crossover gap to operate on a one inch bump improves the suspension small bump compliance to improve both ride and wheel traction (more).