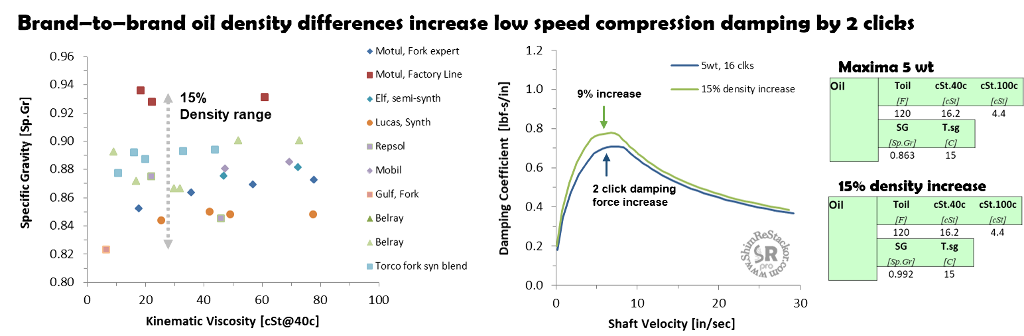

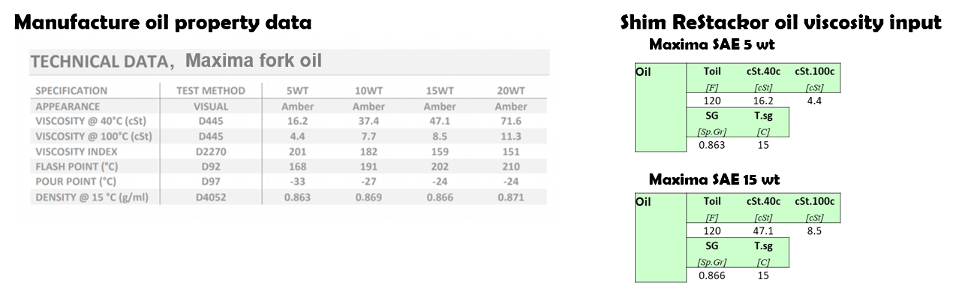

Suspension oils are available in a wide range of viscosities measured in centi-stokes (cSt). Shim ReStackor inputs require the oil viscosity at 40c (cSt.40c) and 100c (cSt.100c), and the oil specific gravity (SG) to define density. Those three parameters define the oil viscosity falloff with temperature (more).

Changing the shock absorber oil viscosity primarily effects damping force at low speed controlled by the clickers and bleed circuits.

Oil viscosity damping

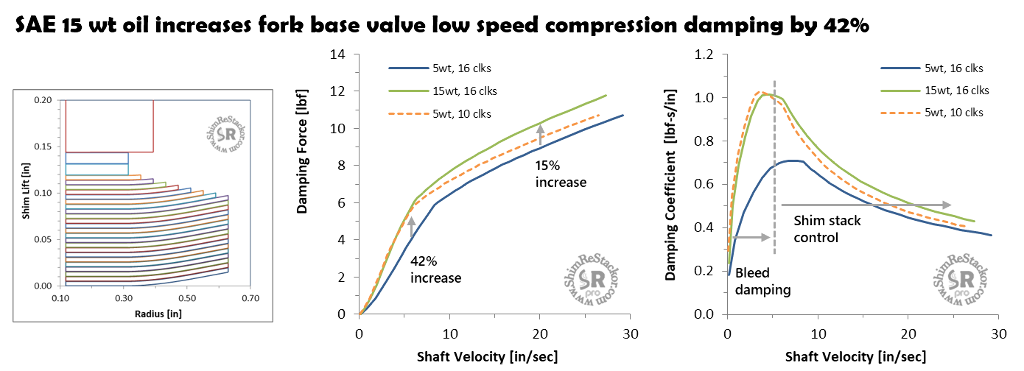

Increasing fork oil viscosity from SAE 5 wt to SAE 15 wt increases the fork base valve low speed compression damping force by 42%. That is equivalent to closing the base valve clickers from a setting of 16 to 10 clicks.

The thicker oil produces higher pressure drops through the bleed circuits forcing the shim stack to crack open earlier. That moves the “knee” of the damping force curve to lower speeds (more).

After the shim stack cracks open at 5 in/sec the damping force increase of the thicker oil is reduced to 15%. Higher pressure drops produced by the thicker oil forces the shim stack to open further partially reducing the effect of the thicker oil.

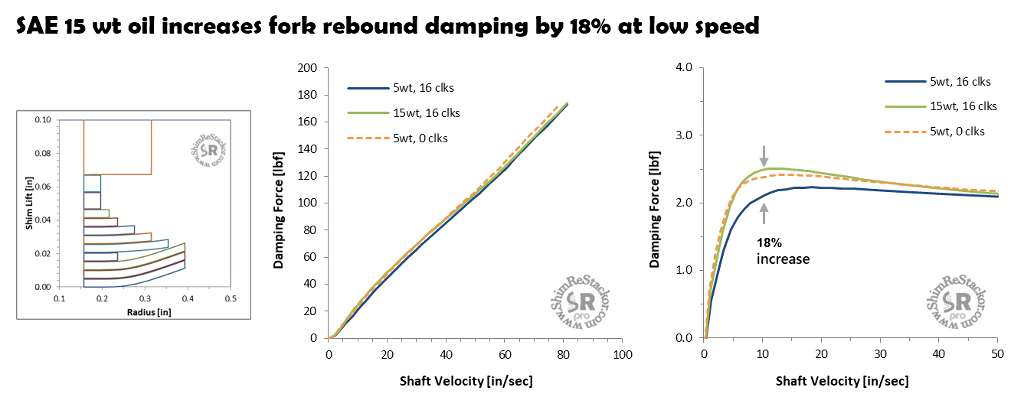

Repeating the above calculations on the fork rebound valve shows an 18% increase in low speed damping using 15 wt oil. The 18% increase is equivalent to running 5 wt oil with the rebound clickers closed.

On the rebound circuit the damping force increase of the thicker oil was less. However, the equivalent clicker change was larger due to the differences in the mid-valve and base valve bleed circuit flow area.

The example illustrates the effect of oil viscosity on damping force is highly dependent on the valve, shim stack and bleed circuit configuration. There is no way to know the effect of thicker oil on damping force without running the specific case of interest.

Oil density

Brand-to-brand differences in oil density range by 15% (more). Higher density oils require higher pressure drops to push the heavier fluid through the shock absorber circuits which increases damping force. Oils with identical viscosities will produce different damping force values due to differences in oil densities.

Running Maxima 5 wt oil with a 15% density increase increases damping force by 9%. That is equivalent to two clicks at 5 in/sec.