Damping targets

From test ride results the rider wants to soften low speed compression for small one inch “trail trash” bumps and stiffen high speed for bumps greater than three inches.

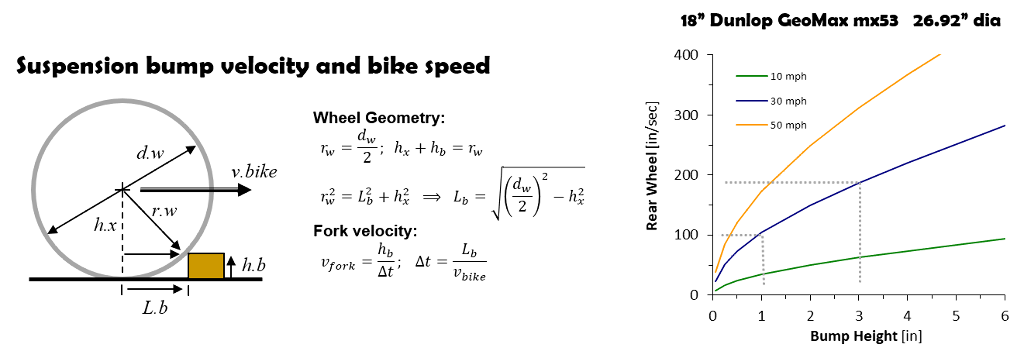

Wheel bump velocity

At a bike speed of 30 mph a one inch bump produces a suspension velocity of 100 in/sec and a three inch bump produces a velocity of 190 in/sec (more).

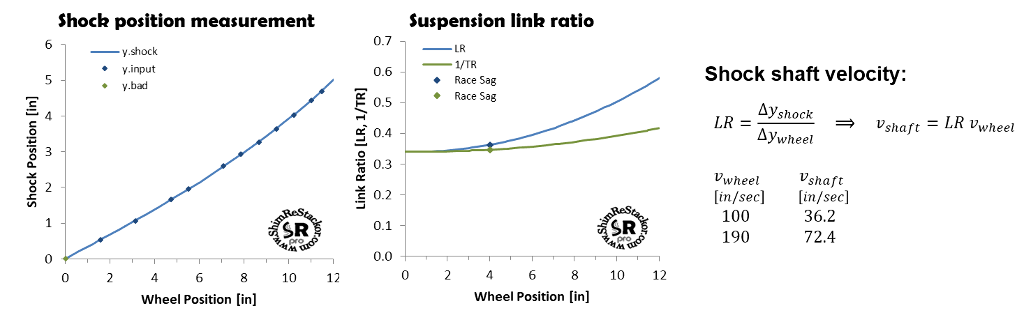

Shock shaft velocity

The suspension link ratio (LR) is computed from measurements of shock shaft and wheel position as the suspension is moved through the stroke. Link ratio specifies the ratio of shock shaft to wheel bump velocity.

For the example where a wheel bump speed of 100 in/sec produces a shock shaft velocity of 36.2 in/sec and the three inch bump velocity of 190 in/sec produces a shock shaft speed of 72.4 in/sec.

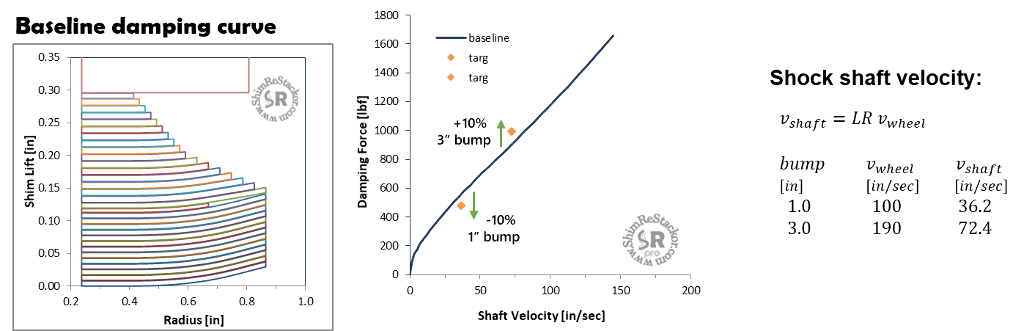

Damping tuning targets

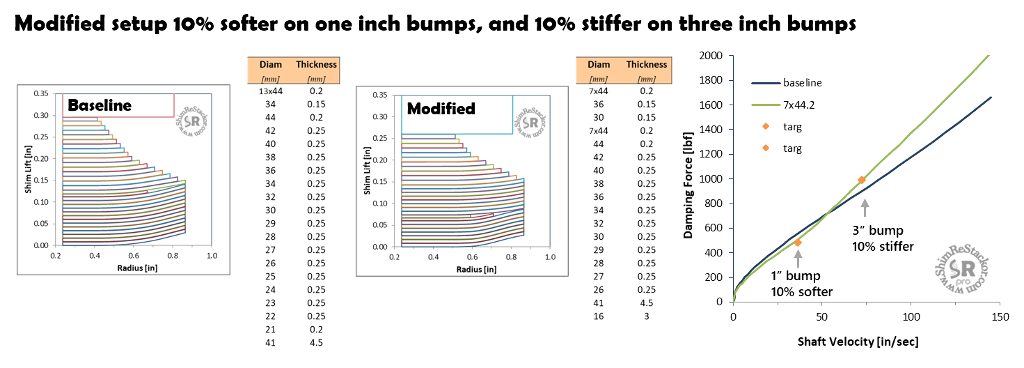

From the test ride results, the rider wants to soften low speed compression damping by 10% over small one inch bumps and stiffen compression damping by 10% on bumps larger than three inches.

Running Shim ReStackor on the current setup gives the damping force curve and the two damping targets for the new setup.

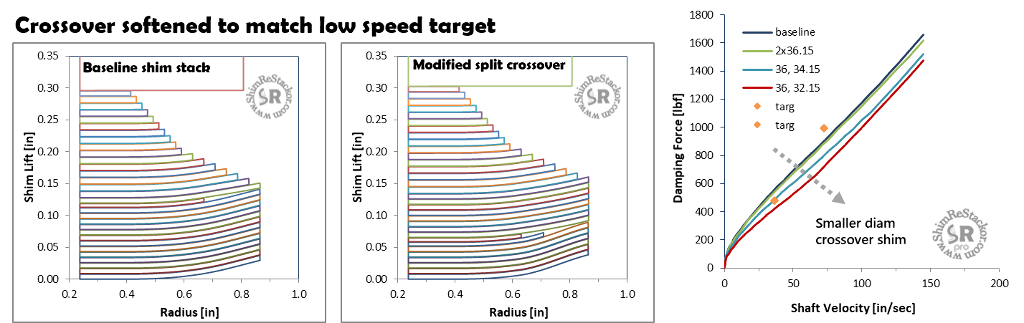

Low speed damping

The baseline shim stack has a crossover. To soften low speed damping the shim stack needs a larger crossover gap and a stiffer high speed stack to hit the +10% target on three inch bumps.

To figure out the crossover needed a series of calculations were run using progressively smaller crossover shim diameters. A split crossover using a 36.15 and 32.15 shims is close to the low speed damping target.

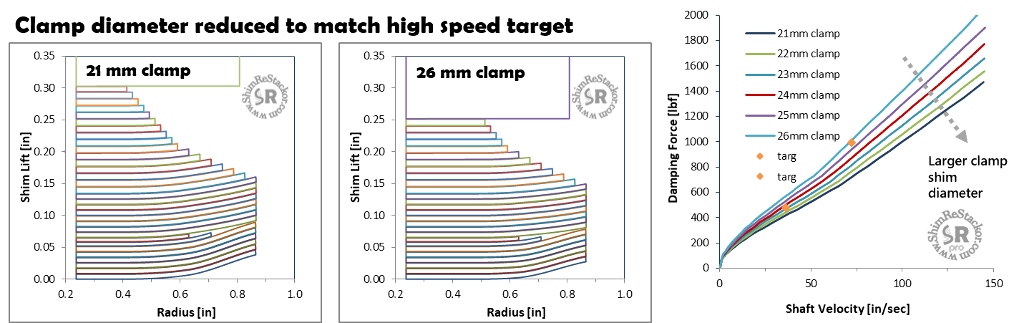

High speed damping

Hitting the 10% increase in high speed damping requires a stiffer high speed stack. A series of calculations were run using progressively larger stack clamp diameters.

A 26 mm stack clamp comes closest to hitting the high speed three inch bump target. With the stiffer high speed stack the crossover needs to be readjusted to stay on the low speed damping target.

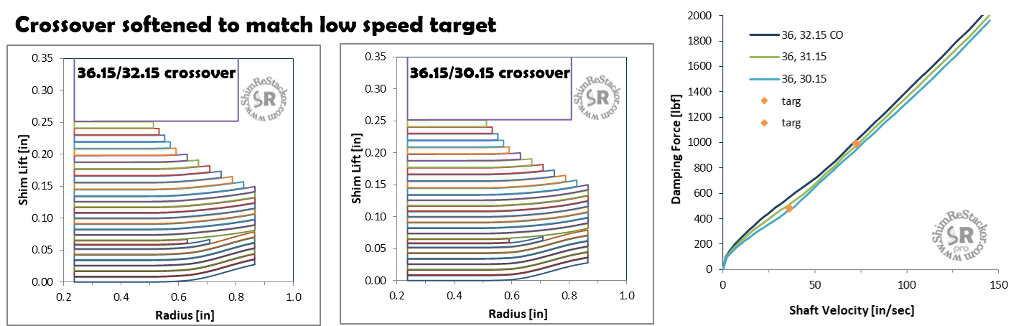

Crossover adjustment

The low speed one inch bump damping target is in between a 30.15 and 31.15 crossover shim.

Using the smaller 30.15 mm crossover and adding a face shim hits both the low and high speed damping targets.

Reshaping damping force curves

There is no secret formula to determine the shim stack modifications needed to hit a specific damping force target. Tuning is simply done through hacking.

For this example: The crossover was tuned to hit the low speed one inch bump damping target. Then the high speed stack was tuned to hit the high speed damping target on three inch bumps.

The interactive crossover used in the configuration coupled with the stiffer high speed stack caused low speed damping to increase with the stiffer high speed stack.

A couple more modifications to the crossover and added face shim hit both the low and high speed targets. In total, 12 runs where needed to reshape the damping force curve.

On a dyno at $50/stroke the modification would cost $600.

In total, 12 runs where needed to reshape the damping force curve and hit the tuning targets.