Shock absorber damping force is tuned by simply hacking around on the shim stack until the desired combination of low speed, high speed and damping force curve shape is achieved.

The capability of Shim ReStackor to rapidly compute complex shim stack configurations and the resulting damping force curve across the entire range of suspension velocities makes tuning simple, easy and intuitive.

- Adding shims makes damping stiffer

- Removing shims does the opposite

- Crossover

- Softer low speed

- Stiffer high speed

- Ring shim

- Stiffer low speed

- Softer high speed

Shim stack theory

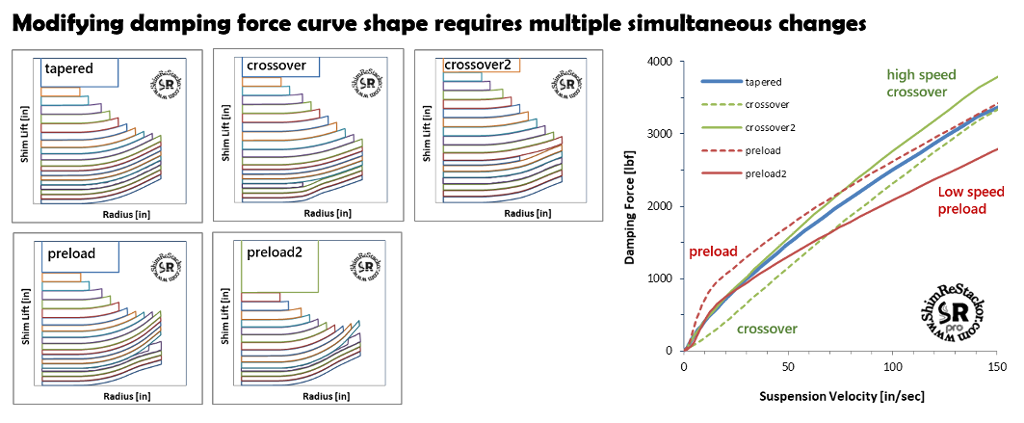

Tapered shim stacks produce a digressive damping force curve. Adding a crossover reduces low speed damping making the damping force curve progressive. Ring shims preload the stack increasing low speed damping which makes the damping force curve more digressive.

Those three features control a wide range of damping force curve shapes giving control of the damping force curve across the entire range of suspension velocities (more).

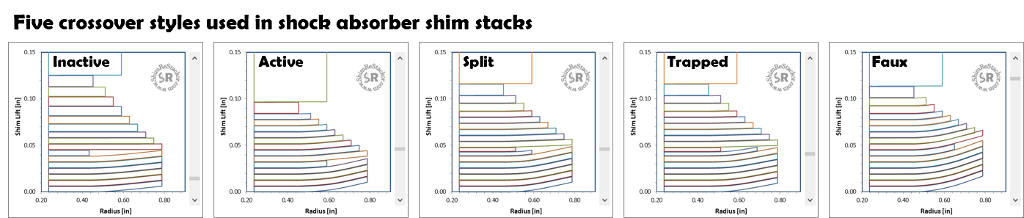

Crossover gaps

There are five different styles of crossover gaps. Each style produces a slightly different damping force curve.

Fine tuning crossovers gives detailed control of low speed damping and the velocity where the shim stack transitions to high speed damping (more).

Five different crossover styles used in shock absorber shim stacks

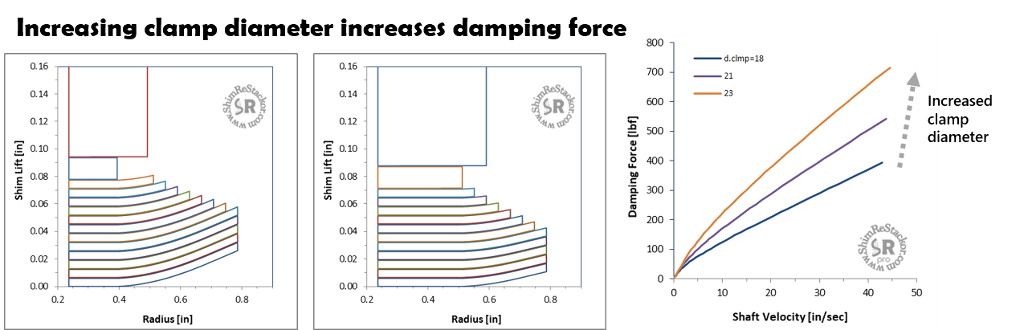

Clamp shim

Increasing the shim stack clamp diameter increases the shim stack stiffness and damping force.

Clamp diameters larger than the valve port inside diameter physically close off a portion of the valve port creating a larger effect than the shim stack stiffness increase alone (more).

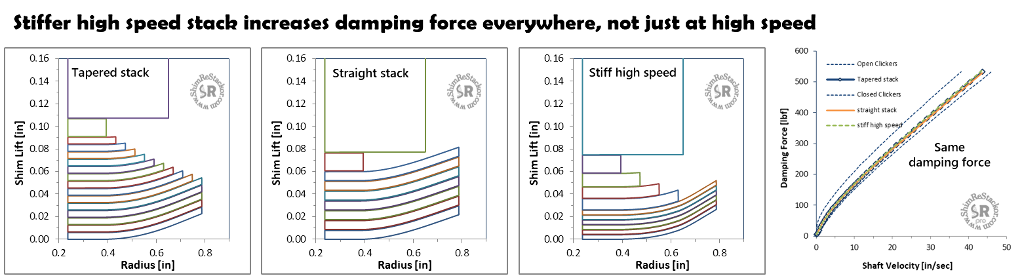

Shim stack taper

Shim stack taper controls the bend radius of face shims and helps prevent kinking of the shims at high lift. Stiffening the stack taper increases the overall shim stack stiffness and damping force.

However, shim stack taper has little influence on the damping force curve shape. That effect is not widely understood by many tuners (more).

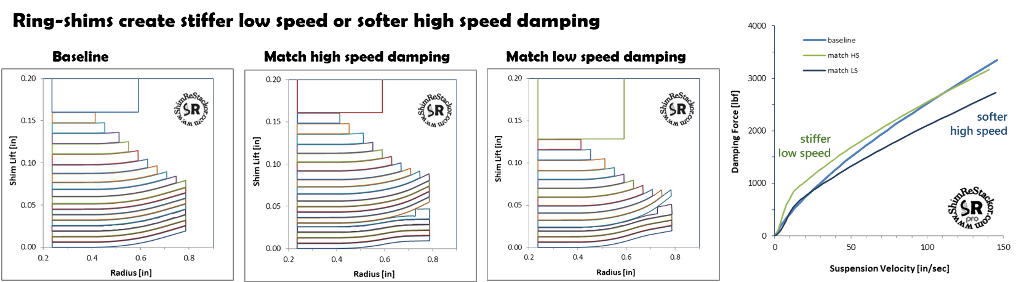

Ring shims

Ring shims preload the shim stack holding the shim stack closed at low speed which increases low speed damping.

Ring shims can be tuned the other way around to soften high speed damping (more).

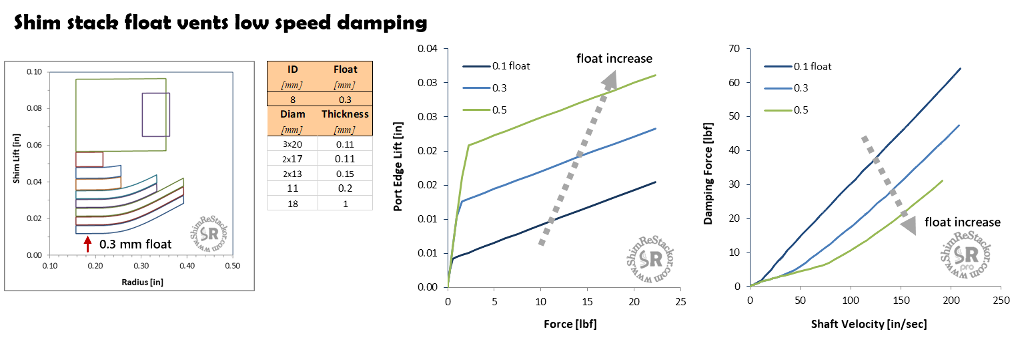

Stack float

Stack float allows the shim stack to physically lift off the valve face and vent low speed damping.

Float delays the suspension speed where the shim stack flow resistance kicks in making the damping force curve softer and more progressive (more).

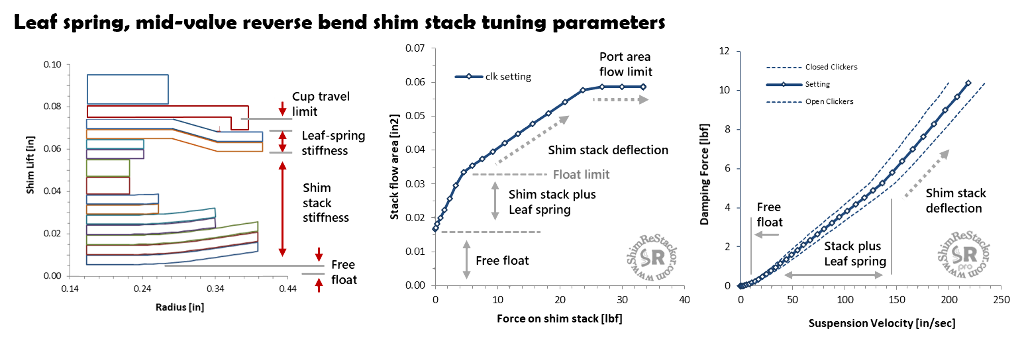

Leaf-spring stack

A reverse bend “leaf-spring” on the top of a floated shim stack bends backwards into the shim stack cup controlling opening of the stack float.

Leaf springs can be setup to control low speed float opening or tuned the other way around as a high speed blow-off system (more).

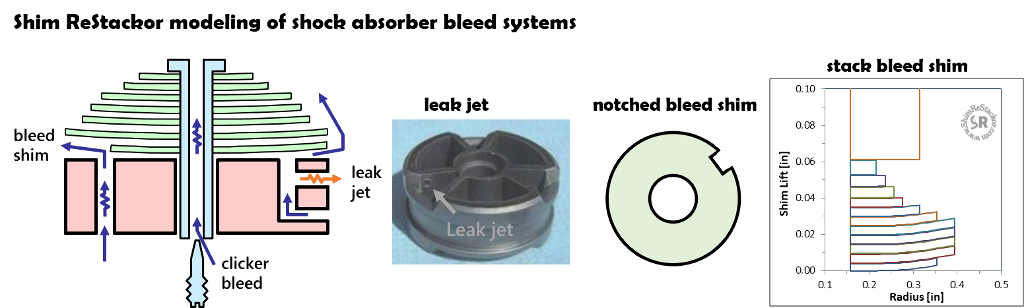

Bleed systems

Bleed systems control low speed suspension motions. Shim ReStackor models clicker bleed, bleed shims, notched bleed shims, leak jets and shim stack float.

The efficiency of each bleed system is slightly different and influenced by changes in oil viscosity (more).