Dyno accuracy

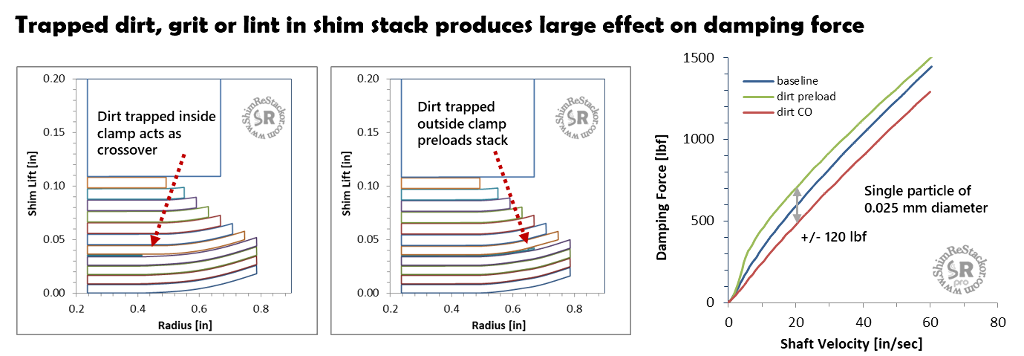

Shim stacks are extremely sensitive to trace contaminants. A single particle from 800 grit sandpaper (0.025 mm diameter) trapped in the shim stack changes the damping force by 120 lbf.

Particles trapped inside of the shim stack clamp produce a crossover gap reducing the damping force. Particles trapped outside of the clamp preload the shim stack driving the damping force up creating a +/- 20% uncertainty in damping force.

For fielded shocks, any dirt, grit or lint trapped in the shim stack is ground up and spit out after a couple of hours of operation. Free of debris the shock returns to the nominal “clean stack” damping force.

Dyno tests, on the other hand, are only run for a couple of minutes. Trace contaminates, in the range of 800 grit sand paper, significantly alter the damping force measured. That creates problems comparing back-to-back tests with subtle differences in shim stack tuning and +/- 20% damping force noise.

800 grit particle trapped in shim stack significantly changes measured damping force

Dyno test-to-test repeatability

Test-to-test repeatability shows up in dyno tests series fine tuning compression damping where several back-to-back tests are run. Through that test series the rebound shim stack is left untouched, however it is not uncommon to see test-to-test drifts in rebound with an occasional rouge test drifting off target by 10% or more.

Failure to repeat rebound raises questions on the fidelity of the compression measurement, which was the goal of the test series.