Shim stack taper high speed damping force

The notion of the high speed stack controlling high speed damping is a widely spread myth.

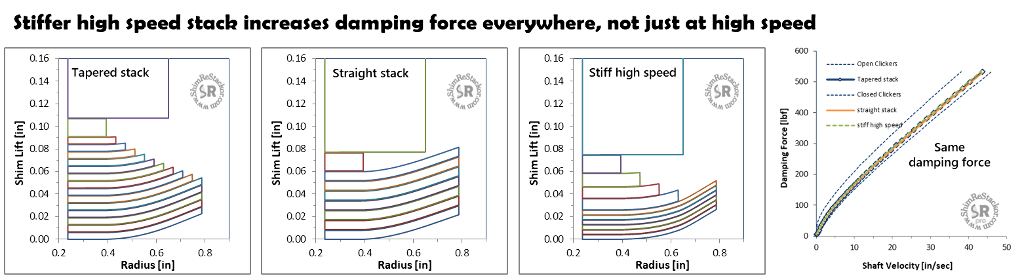

A tapered stack, straight stack or stiff high speed stack can all be tuned to produce the same damping force curve.

Changing the clamp diameter or high speed stack stiffness clearly changes the shock absorber damping force and “feel” of the suspension. But, it does not change the shape of the damping force curve or the split between low and high speed damping.

Tapered, straight and stiff high speed stack all produce the same damping force curve

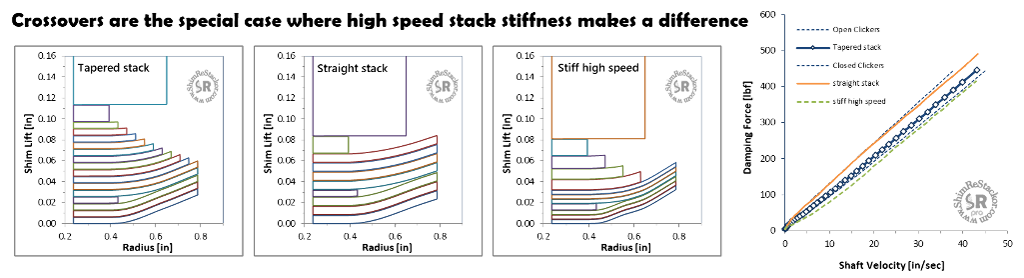

Crossover shim stacks

Crossover shim stacks are the special case where the high speed stack makes a difference. Face shims control low speed damping and the combined high speed stack and face shims control high speed damping.

Installing a 20.15 mm crossover in the above shim stacks shows each stack produces a different damping force curve due to differences in the high speed stack stiffness.

Stiffness of the high speed stack makes a difference in crossover shim stacks

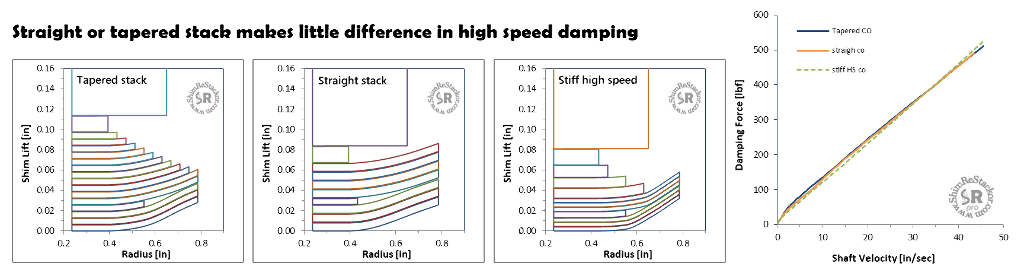

Crossover tuning

However, the crossover in each of the shim stack configurations can be retuned to show the damping force is about the same for all three setups.

The example demonstrates there are often multiple shim stack configurations producing nearly identical damping force curves. The final configuration used is often simply based on the shims on hand at the time.

Multiple shim stack configurations can be tuned to produce nearly identical damping force curves