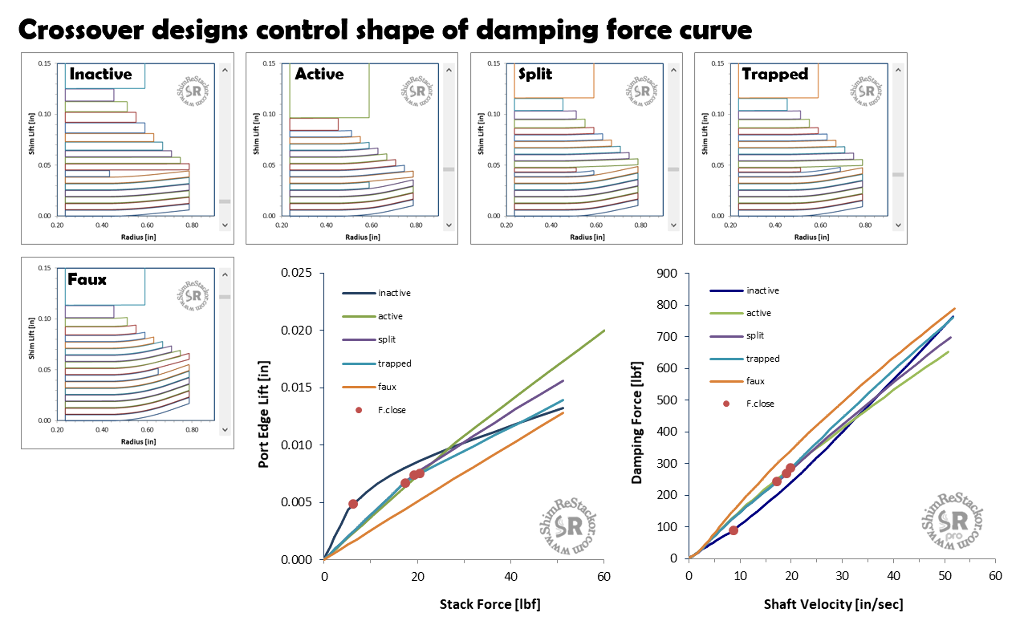

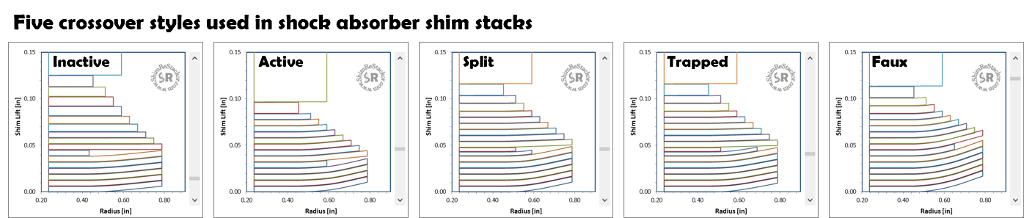

Crossovers split the shim stack into a high and low speed stack. Face shims below the crossover control low speed damping. Shims above the crossover control high speed damping after the crossover closes.

Crossovers soften low speed damping shifting the basic digressive curve shape of a simple tapered shim stack into a linear or progressive damping force curve. Shim stacks use five different styles of crossovers.

Simple tapered shim stack produces a digressive damping force curve

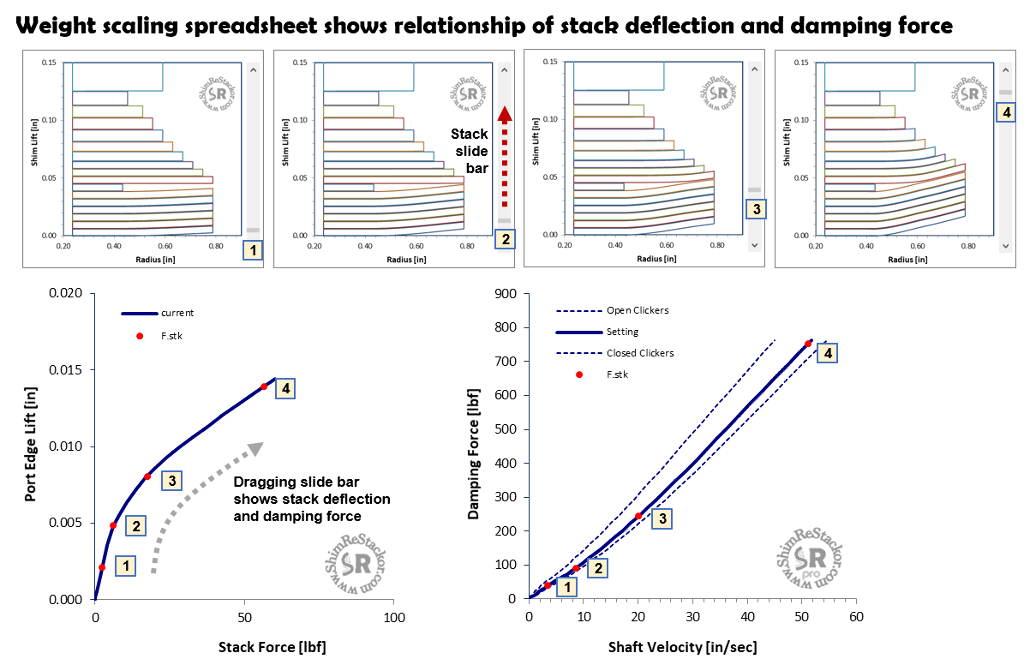

Weight scaling slide bar

The crossover closure velocity can be difficult to spot on a damping force curve, particularly for soft closure events of an interactive crossover.

The Shim ReStackor weight scaling spreadsheet includes a slide bar on the shim stack deflection plot.

Dragging the slide bar pans the shim stack through the deflection range and positions red symbols on each plot indicating the value at that shim stack position.

Panning the slide bar makes it easy to find the crossover closure velocity and subtle events like the influence of a trapped crossover on high speed damping.

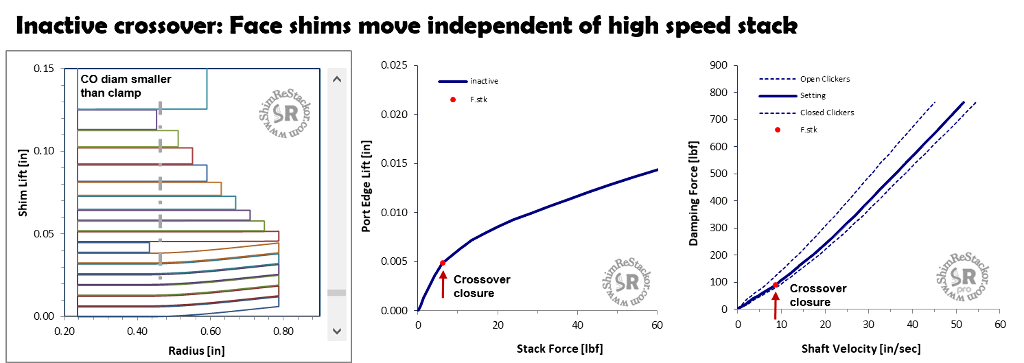

Inactive crossover

An inactive crossover use a shim diameter smaller than the stack clamp. At low speed, before the crossover closes, forces applied to the face shims are directly transferred into the shim stack clamp without deflecting the high speed stack.

After the crossover closes, the face shims transfer force into the high speed stack increasing the shim stack stiffness and damping force.

Inactive crossovers produce a progressive damping force curve.

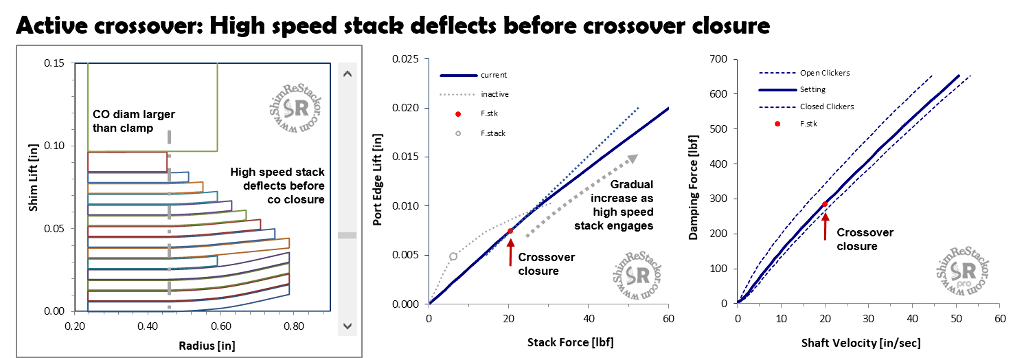

Active crossover

An active crossover uses a shim diameter larger than the stack clamp. The larger diameter increases the stiffness of the face shims and transfers force from the face shims directly into the high speed stack before the crossover closes.

The transfer of force starts to deflect the high speed stack before the crossover closes which delays closure of the crossover gap and produces a softer closure event.

Stiffening the high speed stack on an active crossover stiffens both low and high speed damping.

The softer closure event of an active crossover produces a smoother damping force curve with no sudden increase in damping force when the crossover gap closes.

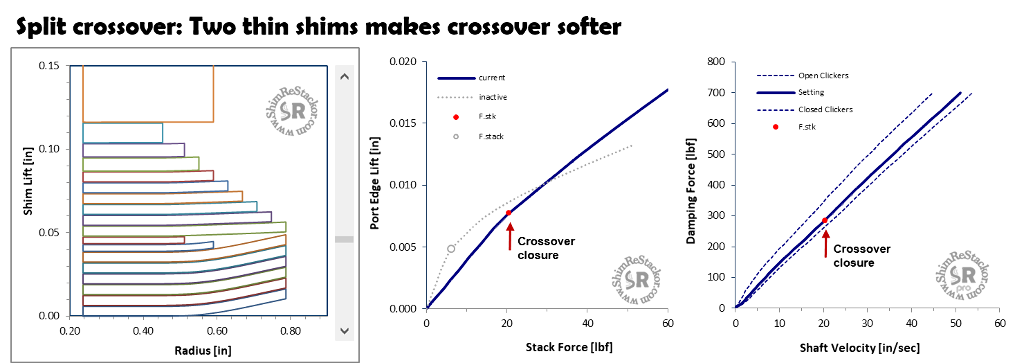

Split crossover

A split crossover uses two shims to form the crossover gap. Split shims smooth the bend radius at the crossover shoulder and help to prevent kinking of the face shims on the sharp corner of a single crossover shim.

By the thickness cubed rule, one 0.2 mm shim is equivalent to eight 0.1 mm shims. Replacing a 0.2 mm crossover with a pair of 0.1 mm shims adds less stiffness to the overall shim stack.

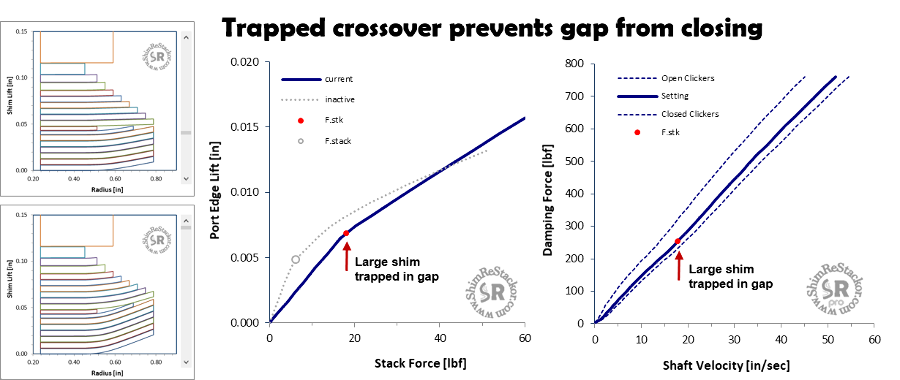

Trapped crossover

A trapped crossover is a split shim crossover where the larger diameter crossover shim becomes trapped in the closing crossover gap.

The trapped shim reduces the effective crossover gap making the shim stack stiffer.

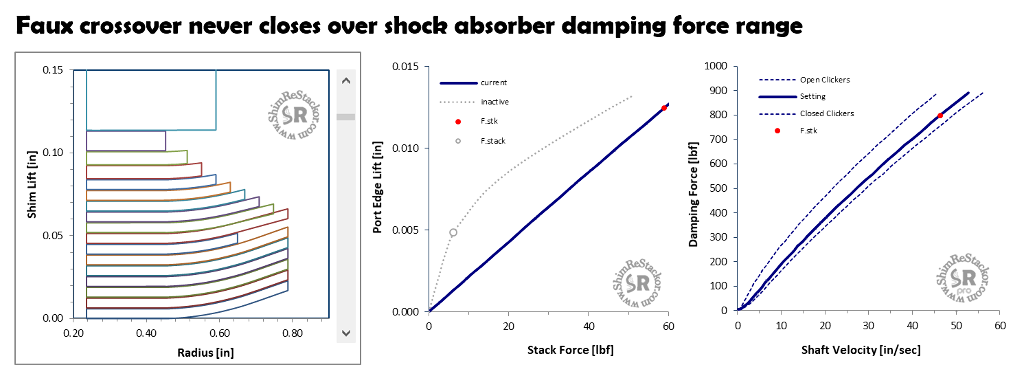

Faux crossover

Faux crossovers transfer force from the face shims into the high speed stack forcing the high speed stack to deflect at the same rate as the face shims. Faux crossovers never close.

Faux crossovers are created by large diameter crossover shims, high speed stacks that are not stiff enough to crush the crossover gap, or a valve port geometry producing little force at the outside edge of the face shim. Shim ReStackor computes either case.

Crossover tuning

The stiffness of crossover shim stacks are controlled by the crossover diameter, the high speed stack stiffness and the stack clamp. The crossover closure velocity is increased by adding face shims, increasing the crossover diameter or crossover shim thickness.

There is no secret formula to figure out the specific crossover style needed to hit a target damping curve. Crossovers are tuned by hacking.

The crossover gap height, shim diameter, number of face shims and high speed stack stiffness are simply determined through hacking the shim stack until the target damping force curve is achieved.

The capability of Shim ReStackor to show how the shim stack deflects, the velocity where crossover gaps close and the influence of the high speed stack on damping force makes tuning of crossovers simple, easy and intuitive.