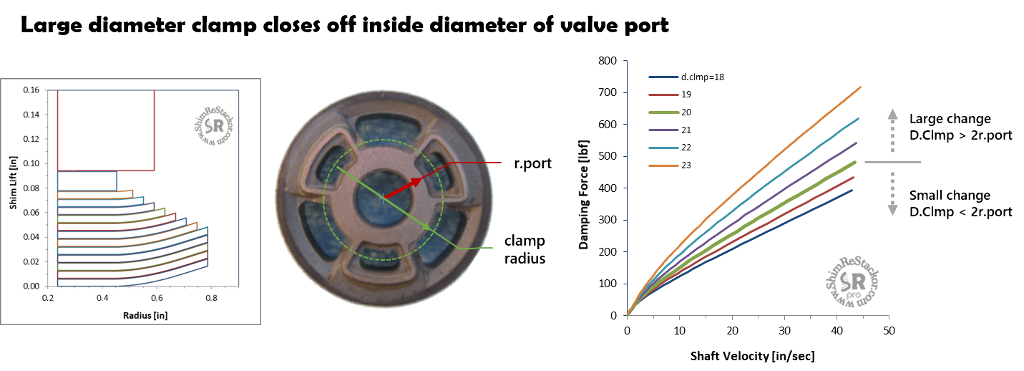

Increasing the shim stack clamp diameter produces a progressive increase in damping force up to the point where the shim stack clamp diameter overlaps the valve port inside diameter (r.port).

Further increases in clamp diameter physically close off a portion of the valve port producing a larger change in damping force due to the reduced port flow area.

Dyno tuners refer to the nonlinear increase of large clamp diameters as an example of the complex behavior of shim stacks. In reality, the nonlinear increase is simply the result of closing off a portion of the valve port.

Large clamp diameters can be a useful tuning aid to obtain more shim stack control when tuning large port diameter valves.

Shim stack clamp washer

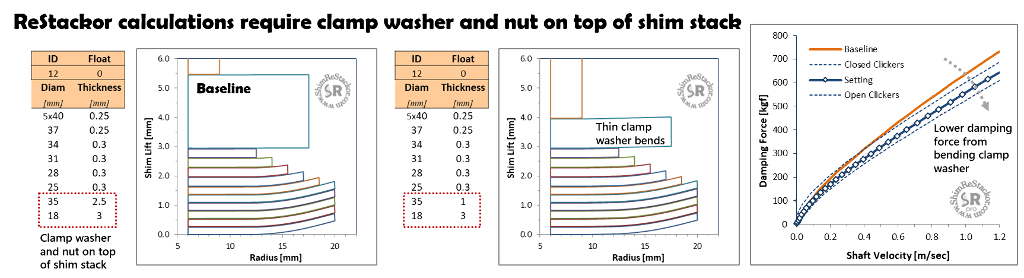

Shock absorbers use thick heavy clamp washers purposely designed to never bend.

However, small deflections of the clamp washer produce significant changes in damping force as demonstrated in the example below.

For accurate results, Shim ReStackor inputs require the final two entries in the shim stack listing to specify the shim stack clamp washer and nut dimensions.

Failure to specify a ridged clamp washer will often cause the calculations to hang.