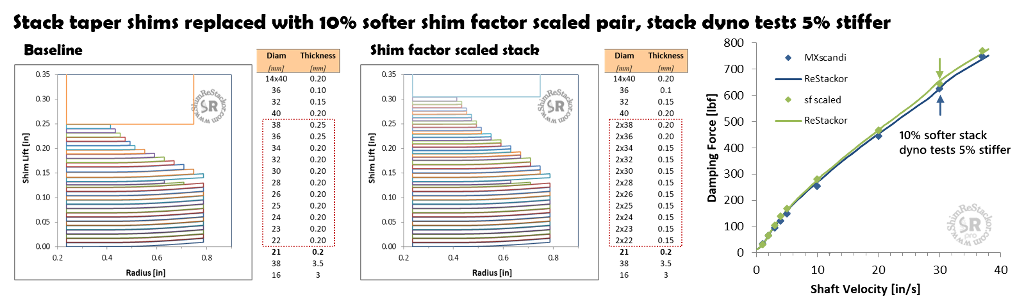

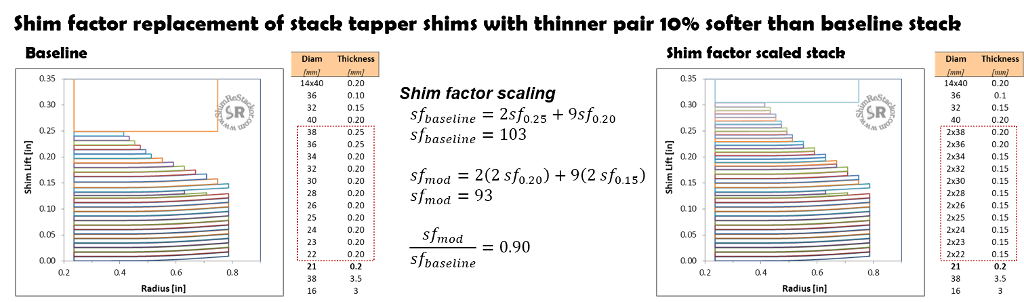

MXScandinavia dyno tested shim factor equivalent stacks on Thumper Talk to determine the accuracy of shim factor scaled suspension setups. The test replaced the 0.20 mm shims in the shim stack taper with a shim factor equivalent pair of 0.15 mm thick shims.

By shim factor theory the replacement stack should be 10% softer. Dyno testing the shim stacks shows the theoretically softer stack actually produces 5% more damping force (data points). Shim ReStackor calculations (lines) verify the dyno test results.

Theoretical 10% softer shim factor scaled stack dyno tests 5% stiffer

Shim friction increases stack stiffness

Friction between the shim interfaces causes the damping force difference. Replacing the stack taper shims with a softer pair of shims doubles the shim interface surface area and the increased surface area increases friction.

The result is the theoretically 10% softer shim stack actually dyno tests to produce a 5% increase in damping force.

Shim ReStackor FEA calculations compute the forces acting on the top and bottom surface of each shim allowing the calculations to accurately determine shim friction and its effect on stack stiffness and damping force.

MXScandinavia dyno tests demonstrate shim friction makes a theoretically 10% softer shim stack deliver 5% stiffer damping. A swing of 15%.

Stack taper shims replaced with shim factor scaled thinner pair