Dyno Accuracy

Shim stack clamp washers are thick, heavy washers purposely overdesigned to never bend. However, hard hits can bend the clamp washer. When bent, the clamp washer significantly reduces the damping performance of a shock absorber.

A “bent” washer does not mean the clamp washer is bent around into a cup shape. Bent means the clamp washer is very slightly displaced from perfectly flat.

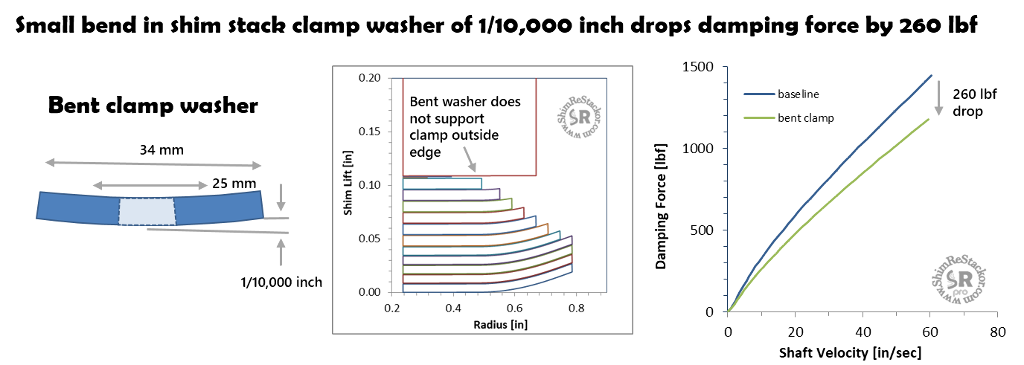

The Shim ReStackor example below evaluates a 35 mm clamp washer bent 1/10,000 of an inch at the outside edge. Assuming a smooth bend, the displacement at the 25 mm clamp shim stack is 0.4/10,000 of an inch.

A bent clamp washer does not support the outside edge of the clamp shim producing an “effective” clamp diameter of zero. As the shim stack deflects, the clamp shim eventually contacts the bent washer, but that requires significant deflection of the face shims.

The end result is a 1/10,000 of an inch bend at the clamp washer edge produces a 260 lbf drop in shock absorber damping force.

To obtain reliable performance clamp washers need to be perfectly optically flat.

Bent clamp washer does not support outside edge of shim stack clamp significantly reducing damping force