Shim factor scaling

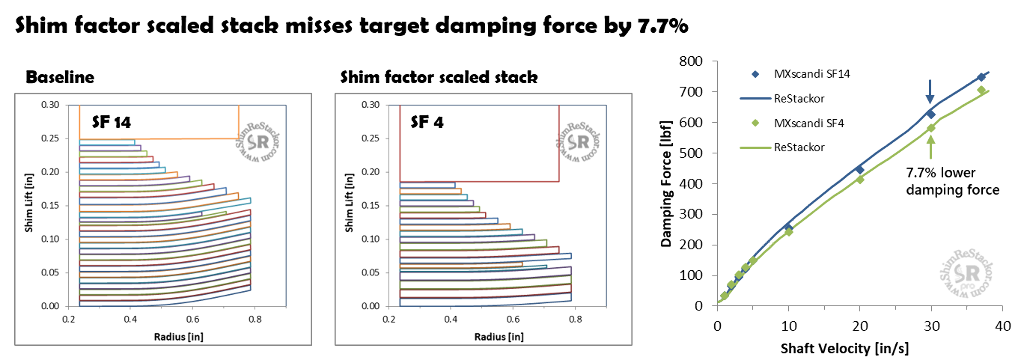

MXScandinavia dyno tested shim factor equivalent stacks on Thumper Talk to evaluate the accuracy of shim factor scaling. By shim factor theory, a stack of 4x40.3 face shims is 3.8% softer than a stack of 14x40.2 shims.

Dyno test results shows the actual difference was approximately double that at 7.7% (data points). Shim ReStackor analysis of the two shim stack configurations shows the same thing (lines).

MXScandinavia dyno testing of shim factor equivalent shim stacks shows 7.7% less damping force

Interactive crossover rm85

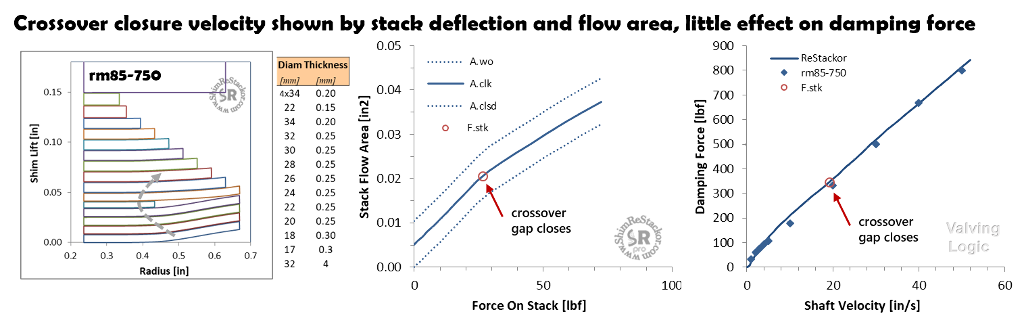

Interactive crossovers use a shim diameter larger than the shim stack clamp. The larger crossover diameter transfers force from the face shims directly into the high speed stack forcing the high speed stack to deflect before the crossover closes. Interaction with the high speed stack softens the crossover closure event (more).

Valving Logic on Thumper Talk demonstrated the performance of an interactive crossover. The damping force data shows no evidence of the crossover closing.

However, Shim ReStackor calculations of the shim stack deflection and stack flow area make it easy to spot the crossover closure velocity at 20 in/sec,

Soft closures of interactive crossover with a soft high speed stack often do not produce any specific “event” in the damping force curve. The data at 20 in/sec where the crossover closes shows that.

Interactive crossover configuration produces a "soft" crossover closure event

High speed stack (mx9)

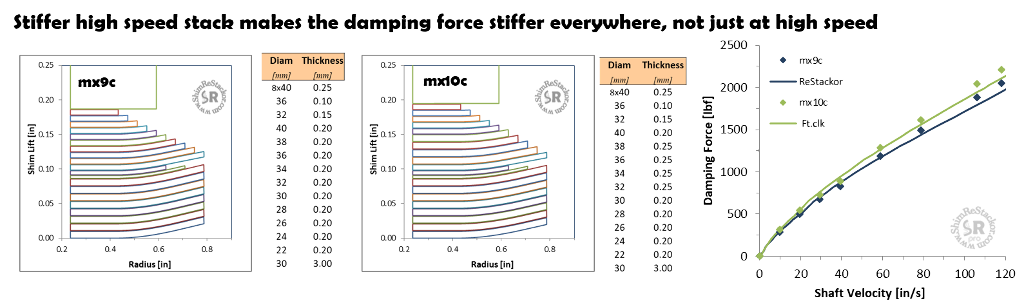

Softening or stiffening the high speed stack changes the damping force everywhere, not just a high speed.

The example below from the MXScandinavia thread on Thumper Talk replaces the 0.2 mm shims in the stack taper with stiffer 0.25 mm shims.

The dyno test results (data points) show the shim stack is stiffer everywhere across the speed range, not just at high speed. Shim ReStackor calculations (lines) show the same thing.

High speed stack stiffness has little influance on high speed damping force measured on the dyno

Faux crossover gap

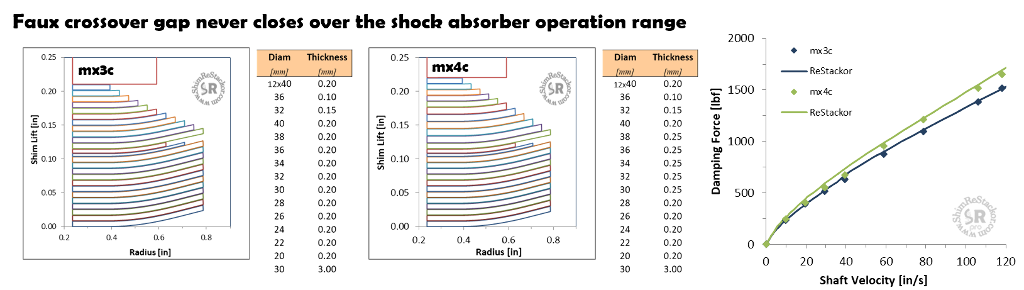

A faux crossover gap never closes. Faux gaps are created by large crossover shim diameters, stiff low speed stacks or soft high speed stacks that do not produce enough force to close the crossover gap. MXScandinavia provides dyno test examples of faux crossovers.

In dyno testing, faux crossovers behave like a interactive crossover. Changes to the low or high speed stack changes the damping force leading many dyno tuners to believe the crossover gap is active.

However, the crossover gap height never changes as the shim stack deflects. The inactive faux crossover shim could be moved further up in the stack forming a simple tapered shim stack giving the same damping force and curve shape.

In dyno testing, there is no way to know the crossover gap is faux until the shock is pushed to high enough speed to observe the crossover closing. Soft closures of interactive crossovers make those events difficult to spot in damping force data.

Faux crossover gap never closes creating confusion in operation of the shim stack